Pattern Design and Modelling Module

This module realizes high computer technology of creation new models by any construction methodic EMKOSEV, COTSHL, MULLER, GRINSHPAN… or own original methodic and also modelling using existed models.

This program doesn’t limit specialist, gives wide opportunity for creative work and executes all technical and routine job.

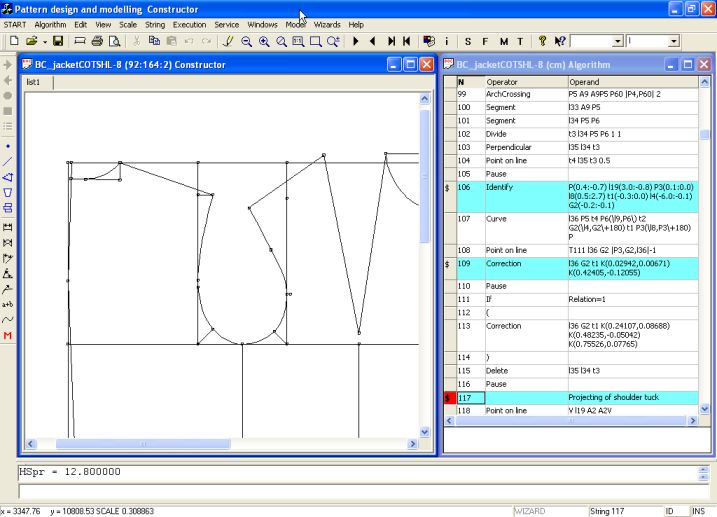

The main point is the display is divided on two windows: Algorithm and Draught. Specialist makes construction by writing his sequence of actions with operators – Algorithm. System executes operators and makes graphical drawing at the Draught.

High computer projecting technology in CAD System GRAZIA providing quick and quality solving all task of Pattern design and modeling:

- Create in one base size any ready-made garment by any construction methodic: EMKOSEV, COTSHL, MULLER, GRINSHPAN… or own original methodicli>

- Create in automate mode pieces of all needed sizes with guarantee quality of clothes

- Precisely and quickly in automate mode create pieces for individual body dimensions accounting bearing

- Prompt changing pieces in case of model modification as changing material properties, additions, fashion orientation

- Prompt automatically reconstruction of pieces for another size typology of body dimensions – Europeans, Asians, Americans,Italians etc

- Automate form table of control measurements and details' specification

Specialist construct clothes in one size, System quickly and precisely execute all above-listed tasks. Usually used next sequence of work stages.

Constructor form information base for it’s construction methodic:

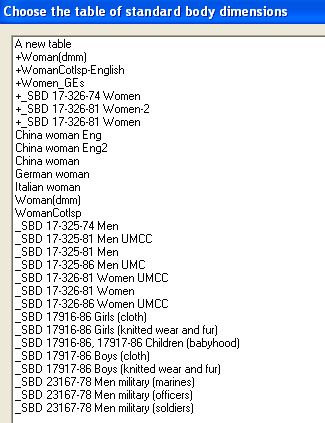

- Order size-height parameters. CAD System GRAZIA include table of standard body dimensions. Constructor can use, correct or create a new table of body dimensions.

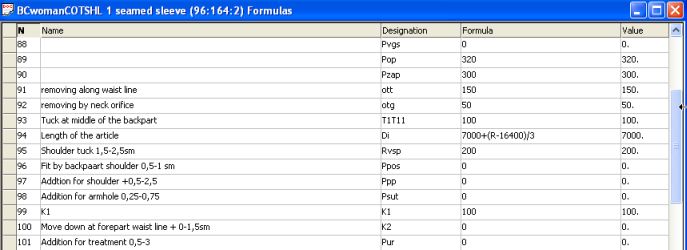

- Then constructor order formulas for design values, parameters of addition and other constant and variable values.

In Subsystem “Pattern design and modeling” display divide on two parts:

Algorithm window – constructor write design process and modeling actions using operators.

Draught window – system execute operators in algorithm and make corresponding graphical projecting.

All design actions are written with operators. Constructor can make any action using operators. All operators by function divide on 5 groups: Actions with points, Actions with lines, Graphical actions, Actions with details and Structure actions.

During making operator (for example, to make point on the line or to make line) constructor get help of Wizard that write in help string what objects and values it necessary to order to execute operator.

So specialist for creative work only have to know how make its idea in hand and System Wizard helps to realize ideas in GraziaCAD.

CAD System GRAZIA is completely open system that allows creating any garments by any methodic and making modelling.

As distinct from graphical pattern design analytical construction allows to write and realize interdependence of mating details. Changing in one details promote automate correct changing in all corresponding and derivative pieces and sections.

It important to note there 2 kinds of interdependence. First kind of interdependence supposes making length of line in dependence of length of another line (for example construction of sleeve’s armhole depend of length of armhole). Second kind of interdependence supposes take into account not only length of line and also shape of the line. To construct line using length and shape of another line.

Grading is the most important task of pattern design. CAD System GRAZIA solve this task in automate mode by repeating execution of algorithm with corresponding body dimension – automatically reconstruction model in every size and height with corresponding values body dimension. This way is more quickly and more precisely than gradation. In every size-height system construct model and save shape of pieces. Time of grading in CAD System GRAZIA take from several seconds to pair of minutes depends of computer configuration and quantity of details in model.

System guarantee in every size-height interconsistency between construction elements as collar and neck orifice, armhole and sleeve’s armhole etc.

Operator “If …, then …, else …” provide making constructive differences in different sizes. For example, in construction of skirt it may be one or two tucks in depends of value total tuck at back width of the skirt. Using operator “If …, then …, else …” in small sizes it would be one tuck at the back width of the skirt, in big sizes it would be two tucks at the back width of the skirt. System automatically control execution of condition in every size-height to make correctly constructive decision.