Marker Making Module

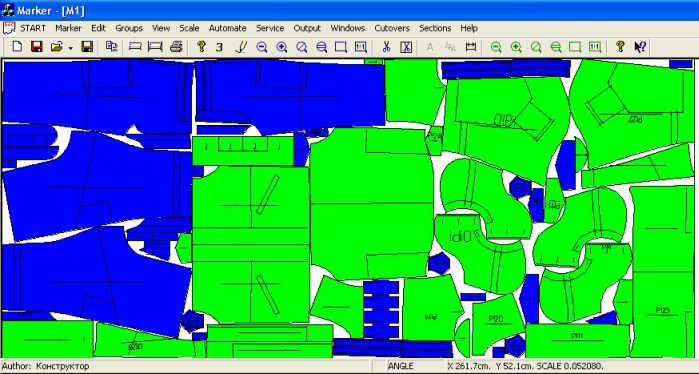

CAD Module makes optimal markers layout in accordance with technology requirements in Lay-up Task using manual, automatically or semi-automatically modes.

The base of marker making process is a mathematical method of geometric projecting that provide automate realizing of geometric and technological requirements, high precision and speed of projecting.

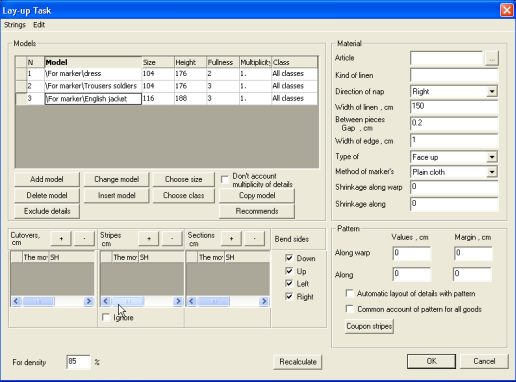

To form Lay-Up Task it’s necessary to choose Models, sizes and heights, detail’s class (kind of material), multiplicity, Kind of linen, Nap direction, Width of material, Width of edge, Gap between pieces, Type of laying and Method of lay up marker. Also it possible to order Value of shrinkage, Size of pattern, defective zones, Overcuts, Sections and other parameters.

System can define combinations of sizes and heights that give optimal results in lay-up.

System has 3 main modes of projecting.

- Automatically mode. All pieces in accordance with technological requirements are automatically lay up without participation of specialist. This mode is very quickly and easy-to-use but it not always keeps cutting requirement and long-term professional experience of specialist.

- Manual mode. All pieces in manual mode specialist layout with handy tools. This mode spends more time but gives all opportunity to create economic and technologic markers. This mode allows to apply experience of specialist, features of cutting devices, material with pattern and others conditions.

- Semi-automatic mode. Some pieces marker can manually layout as he want and other pieces are layout in automatically mode. Specialist may stop automatically mode at any moment change location of some pieces or make other changes and load automatically mode again. This mode gives opportunity to use professional experience of Specialist and speed of Computer. This mode allows to make economic and technologic markers most quickly.

Semi-automatically modes give most effective and technological result. Creation of semi-automatically mode is based on special mathematical methods of geometric projecting is very difficult so this mode is absent in most domestic and foreign CAD Systems.

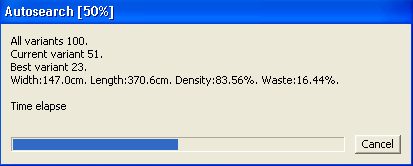

Automatically mode has window Autosearch that show information about quantity of layout variants, process of layout, the current best variant ant it’s parameters. The best current variant is on the screen and it possible to see it parameters: length of the marker, emptiness and density.

Marker Making Module gives opportunity to make operations with single piece: rotation for any angle, cut detail, bend, come out from edge, 5 ways of layout pieces on printed, plaid or stripe material with mating by pattern lines.

Subsystem realizes reasonable requests of specialist of fabrics and educational institutes.

Marker can be output to narrow or large-format plotter. In case of output to narrow format plotter the layout marker can be automatically divide on to two stripes that then joined by sticky tape. The default of joining not more than 0,5 mm at 7 meters. A narrow plotter costs 3-4 times less and uses almost any kind of paper.

Printed in natural size on the paper marker can be used as marking on the flooring material.

The layout marker can be preparing to make cutting with Automatic Cutting Devices.

The quality of marker is one of the main factors of material economy. This factor has a direct influence on prime cost and competitiveness of goods.

But layout marker must be not only economic but technologic. It has to take into account the material’s pattern, a method of markers layout and technology and equipment requirements etc.

GraziaCAD gives an opportunity to use the most effective mode – semi-automatically. It allows to combine professional experience of Specialist and speed of Computer to make technologic and economic markers.